Understanding Diecast Enclosures

Diecast enclosures are essential components in a wide array of industries, providing crucial protection for sensitive electronic and electrical components. Choosing the right enclosure is paramount to ensuring the longevity, safety, and performance of the devices they house. This guide delves into the key factors to consider when selecting diecast enclosures, helping you make informed decisions that align with your specific needs. Understanding the fundamentals of these enclosures is the first step in making the right choice for your projects.

What are Diecast Enclosures

Diecast enclosures are manufactured using a process called die casting, where molten metal is injected under high pressure into a mold (die). This process allows for intricate designs and precise dimensions, making them ideal for complex electronic devices. They are known for their strength, durability, and ability to withstand harsh environmental conditions. These enclosures are commonly used in electronics, telecommunications, automotive, and aerospace applications. The inherent properties of die-cast materials, such as aluminum and zinc, contribute to excellent heat dissipation, shielding against electromagnetic interference (EMI), and overall protection against physical damage.

Materials Used in Diecast Enclosures

The most common materials used in diecast enclosures are aluminum alloys and zinc alloys. Aluminum offers excellent strength-to-weight ratio, superior corrosion resistance, and efficient heat dissipation, making it a popular choice for a wide range of applications. Zinc alloys are another option, known for their high dimensional accuracy, good mechanical properties, and ability to be easily plated or painted. The choice of material often depends on the specific application, the environmental conditions the enclosure will be exposed to, and the required performance characteristics. Careful consideration of these factors is crucial to ensure the enclosure effectively protects the internal components.

Benefits of Using Diecast Enclosures

Diecast enclosures offer several significant advantages over other types of enclosures. Their robustness provides excellent protection against physical impacts, vibrations, and harsh environmental factors such as moisture and dust. The die-casting process allows for the creation of complex geometries and integrated features, such as mounting points and heat sinks, which simplifies the design and assembly of electronic devices. Furthermore, the inherent shielding properties of the metal materials protect the internal components from electromagnetic interference (EMI), ensuring the proper function of sensitive electronics. Diecast enclosures are also known for their dimensional stability and long lifespan, making them a reliable choice for critical applications.

Factors to Consider When Choosing Diecast Enclosures

Selecting the right diecast enclosure involves careful consideration of several key factors. These factors ensure that the enclosure will effectively protect the housed components, perform optimally, and meet the specific requirements of the application. Each factor plays a crucial role in the overall functionality, durability, and longevity of the device. By carefully evaluating these aspects, you can make an informed decision and select an enclosure that perfectly fits your needs.

Size and Dimensions

The size and dimensions of the diecast enclosure must be appropriate for the internal components it will house. Measure the dimensions of the circuit boards, connectors, and other components to ensure they fit comfortably within the enclosure. Consider the need for adequate space for cooling, ventilation, and any additional features, such as connectors or displays. Standard sizes are available, or custom designs can be specified to meet unique requirements. Ensuring the internal components fit properly is crucial for preventing damage or malfunctions, and it also facilitates ease of assembly and maintenance. Accurate measurement and careful planning are essential to choose the correct size.

Material and Durability

The material of the diecast enclosure directly impacts its durability and ability to withstand environmental conditions. Aluminum alloys offer excellent strength and corrosion resistance, making them suitable for a wide range of applications. Zinc alloys provide good mechanical properties and can be easily plated or painted. Consider the environmental factors the enclosure will be exposed to, such as temperature extremes, moisture, dust, and chemicals. For harsh environments, choose materials with high resistance to corrosion and impact. Ensure the material can withstand the expected operating temperatures and the potential for physical damage. Selecting the right material is essential for the long-term reliability of the enclosure and the components inside.

Ingress Protection Rating (IP Rating)

The Ingress Protection (IP) rating indicates the level of protection an enclosure provides against solid objects (dust) and liquids (water). The IP rating is expressed as two numbers; the first number indicates protection against solid objects, and the second number indicates protection against liquids. Higher numbers indicate a greater degree of protection. For example, an IP65-rated enclosure is dust-tight (6) and protected against water jets (5). Choose an IP rating appropriate for the environment in which the enclosure will be used. Consider the potential for dust, moisture, and other contaminants. Selecting the correct IP rating ensures the internal components are protected from environmental hazards, and the equipment can operate reliably.

Environmental Conditions

Consider the environmental conditions the diecast enclosure will be exposed to. This includes temperature variations, humidity levels, exposure to sunlight, and the presence of corrosive substances. For outdoor applications, choose enclosures with UV resistance and corrosion-resistant materials. If the enclosure will be exposed to extreme temperatures, ensure the material and design can withstand those conditions. Proper ventilation may be necessary to dissipate heat and prevent condensation. Account for any potential hazards, such as dust, chemicals, or physical impacts. The enclosure must be able to withstand the specific environmental challenges of its intended location.

Design and Customization Options

Diecast enclosures offer a wide range of design and customization options to meet specific requirements. This flexibility allows for optimized performance, aesthetics, and ease of use. Customization can include modifications to the enclosure’s shape, size, and features, allowing for tailored solutions that fit unique applications and requirements. Carefully consider these customization options to achieve the best results for your project.

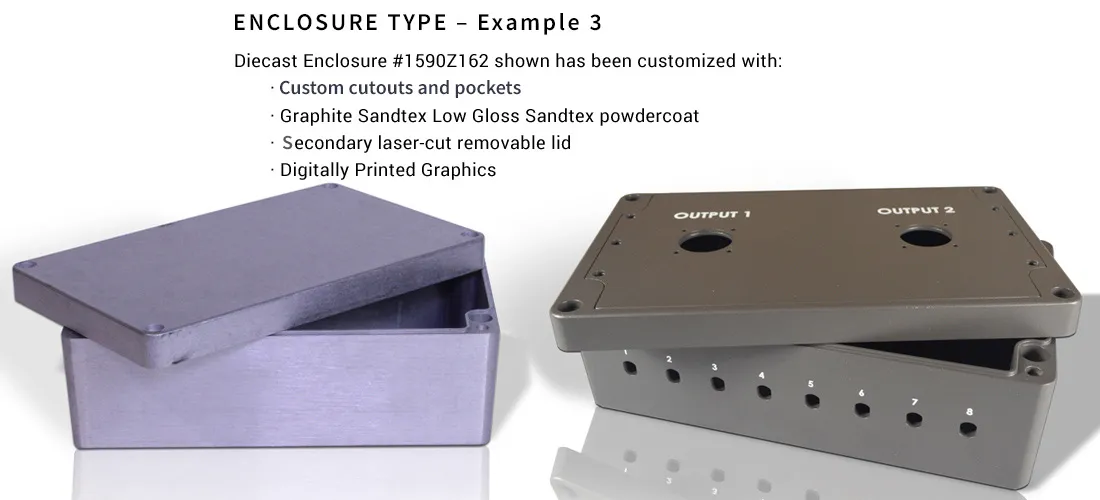

Standard vs. Custom Diecast Enclosures

Standard diecast enclosures are readily available in a variety of sizes and configurations, offering a cost-effective solution for many applications. However, custom enclosures are often necessary to meet specific design requirements or to accommodate unique components. Custom enclosures provide greater flexibility in terms of dimensions, features, and materials. They may include custom cutouts, mounting holes, and surface finishes. The choice between standard and custom enclosures depends on the complexity of the project and the specific requirements. If the components do not fit a standard enclosure, or special features are needed, a custom design is the best option.

Customization Processes

Customization processes for diecast enclosures involve several steps. These start with a detailed design phase, where the enclosure’s specifications are defined, considering the internal components, required features, and environmental conditions. Then, CAD (Computer-Aided Design) software is used to create detailed drawings and models. Prototypes are often created for testing and verification. The die-casting process creates the enclosure, followed by finishing operations, such as machining, surface treatments (e.g., powder coating, anodizing), and assembly. The process ensures the enclosure meets the required dimensions, performance, and aesthetic standards, resulting in a custom-made solution that precisely fits your needs. Collaboration with experienced manufacturers is vital for a successful customization process.

Selecting the Right Supplier

Choosing the right supplier is crucial for the success of your diecast enclosure project. This involves considering a variety of factors to ensure the supplier can deliver high-quality enclosures on time and within budget. Research and due diligence are essential steps in finding a reliable partner who aligns with your project’s needs.

Experience and Expertise

The supplier’s experience and expertise in die casting and enclosure manufacturing are critical factors. Look for suppliers with a proven track record of producing high-quality diecast enclosures for similar applications. Assess their knowledge of materials, design, and manufacturing processes. A supplier with extensive experience can offer valuable insights, provide design assistance, and ensure the enclosure meets the required specifications. Their expertise minimizes risks and ensures efficient and effective project execution. Review their previous projects, customer testimonials, and case studies to assess their capabilities.

Quality Certifications

Quality certifications, such as ISO 9001, demonstrate the supplier’s commitment to quality management systems. These certifications ensure that the supplier follows established procedures, maintains rigorous quality control, and consistently delivers high-quality products. Other relevant certifications may include industry-specific standards or environmental certifications. Verify the validity of the certifications and their scope. A supplier with quality certifications is more likely to produce reliable and consistent results, which minimizes defects, delays, and potential issues.

Customer Reviews and Testimonials

Customer reviews and testimonials provide valuable insights into the supplier’s performance and customer satisfaction. Research online reviews, ask for references, and contact previous customers to learn about their experiences. Pay attention to the supplier’s responsiveness, communication, and problem-solving abilities. Assess the quality of their products, their adherence to deadlines, and their overall level of service. Positive reviews and testimonials indicate a reliable and customer-focused supplier. They provide reassurance that the supplier is likely to meet your needs and provide a positive experience.

Cost and Lead Time

Cost and lead time are important considerations when selecting a diecast enclosure supplier. Balancing these factors is crucial to ensure the project aligns with the budget and timeline. Thorough evaluation of these factors will help you make the most suitable decision.

Pricing Considerations

Obtain detailed quotes from multiple suppliers, comparing the pricing for the enclosures, including any associated costs, such as tooling, finishing, and shipping. Understand the factors that influence the price, such as the complexity of the design, the materials used, and the production volume. Consider the total cost of ownership, including long-term maintenance and potential replacement costs. Evaluate the cost-effectiveness of the supplier’s offerings. Analyze the value offered by the supplier, considering both price and quality. The goal is to find the optimal balance between cost and quality to meet the project’s financial requirements.

Lead Time and Production Timeline

Determine the lead time required for the supplier to produce and deliver the diecast enclosures. This includes the time for design, tooling, prototyping, manufacturing, and shipping. Discuss the timeline with the supplier and ensure it aligns with the project’s schedule. Consider any potential delays or challenges that could affect the production timeline. Understand the supplier’s capacity and their ability to meet the required volume within the given timeframe. A realistic lead time is crucial for keeping the project on schedule. It is crucial to find a supplier capable of delivering the enclosures on time to avoid potential setbacks.

Conclusion

Choosing the best diecast enclosure involves a detailed evaluation of various factors, from understanding the materials and benefits to the specific application requirements and the selection of a reliable supplier. By carefully considering the size, material, IP rating, environmental conditions, design options, and supplier qualifications, you can ensure that the enclosure effectively protects the housed components and meets all project needs. Prioritizing quality, reliability, and cost-effectiveness will contribute to the success of the project and the long-term performance of the device. Taking the time to make informed decisions in the initial phases will result in significant benefits throughout the lifecycle of the project. The right diecast enclosure is an investment in the longevity and functionality of your product, so make the right choice!