What is Diecast Undercut

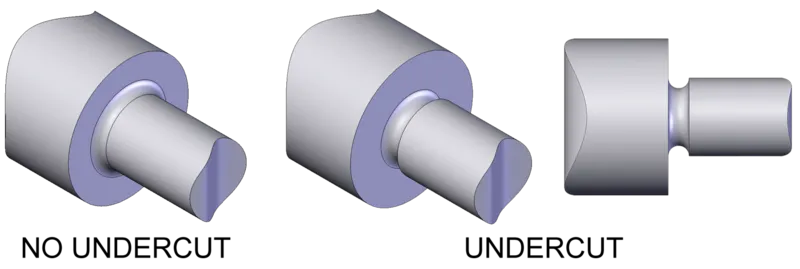

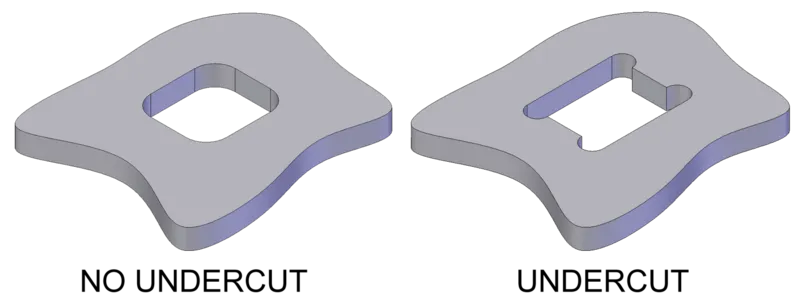

Diecast undercut is a crucial aspect of the die casting process that allows for the creation of complex part geometries, specifically those with features that would otherwise be impossible to produce using standard die casting techniques. An undercut refers to a feature on a casting that prevents its straightforward ejection from the mold. This could be an internal thread, a lip, a groove, or any other protrusion that would get caught on the mold during ejection. Successfully managing undercuts involves the use of specialized mold designs and techniques to ensure the part can be released without damage and that the overall manufacturing process is efficient and cost-effective. Understanding and implementing diecast undercuts is critical for industries that rely on intricate and complex parts like automotive, aerospace, and consumer electronics.

The Importance of Diecast Undercut

The importance of diecast undercuts lies in their ability to significantly enhance design freedom and functionality. Without the capability to create undercuts, product designers are severely limited in the features they can incorporate into their parts. This limitation can affect the overall design, the performance of the product, and potentially the manufacturing costs. Undercuts enable the creation of parts with internal threads, complex geometries, and other features that are often essential for product assembly and functionality. Furthermore, incorporating undercuts can reduce the number of parts required in a product, simplifying assembly and potentially decreasing overall production expenses. This versatility makes diecast undercut an indispensable technique in modern manufacturing and product development.

Understanding the Undercut Process

The undercut process in die casting involves several intricate steps that require precision and careful planning. It generally requires the use of moving mold components, such as slides, lifters, or cams, that are designed to retract before the part is ejected. These mechanisms temporarily create space allowing the undercut features to clear the mold. The process must be carefully orchestrated to ensure that these moving components are correctly positioned during the casting, cooling, and ejection phases. The design of the undercut itself, including its dimensions and angle, is critical to ensure the mold can be successfully separated without damaging the part. The complexity of the undercut process often adds to the cost and time of production, but is often justified by the enhanced design capabilities it provides.

Steps to Achieve a Successful Diecast Undercut

Achieving a successful diecast undercut involves a series of well-executed steps, each contributing to the overall precision and quality of the final product. From the initial design phase to the final ejection, every stage requires careful attention to detail. Effective communication between the design and manufacturing teams is critical to ensure that the design incorporates the right angles, draft, and appropriate features to accommodate the undercut. Advanced simulation software is often utilized to predict how the metal will flow and how the mold components will interact, helping to identify and rectify potential problems before production begins. Regular inspection throughout the process is crucial to verify the accuracy and integrity of the undercut features, and make sure they are working as intended.

Step 1 Preparing the Mold

The first step involves meticulous preparation of the die casting mold. This begins with designing the mold to incorporate any necessary slides, lifters, or cams that will be used to create and manage the undercut features. The mold must be manufactured with precision, and the moving components need to fit together with minimal gaps to prevent leakage of molten metal. Before casting, the mold is preheated to an appropriate temperature to ensure that the metal flows correctly and to avoid thermal shock. The mold surface is also treated with a lubricant to facilitate the ejection of the cast part. Proper mold preparation is critical to avoid defects such as flash, distortion, and premature wear, which will ensure the long-term performance and efficiency of the entire die casting process.

Step 2 Creating the Undercut Features

The second step entails the precise creation of the undercut features within the mold. This is achieved through the use of specialized mold components, such as slides or cams, that move into position during the casting process. These components define the undercut geometry, creating the necessary space for the features. The movement of these components must be carefully timed and controlled to ensure they retract before the part is ejected. Precise alignment and synchronization of all moving parts are critical to prevent metal leakage, deformation, or damage to the part. The quality of the undercut features depends on the precision of the mold components and the accuracy of the movement mechanisms, which must be checked regularly for wear and tear to maintain the integrity of the undercut.

Step 3 Casting the Metal

After mold preparation and undercut feature creation, the molten metal is injected into the mold cavity under high pressure. The pressure ensures that the metal fills all the intricate details, including the undercut features. The metal must be injected at the correct temperature and flow rate to avoid defects such as porosity or cold shuts. The mold design must also provide appropriate venting to allow trapped air to escape, preventing air pockets that could compromise the structural integrity of the casting. Throughout the casting phase, the mold is cooled to allow the metal to solidify. The cooling process is carefully managed to prevent distortion or stress, ensuring that the undercut features are preserved accurately during the solidification phase.

Step 4 Removing the Undercuts

Once the casting has cooled and solidified, the undercut features are removed by retracting the moving mold components. This typically involves the slides, lifters, or cams that were used to create the undercuts. The timing and sequence of component retraction are carefully orchestrated to ensure a clean release of the part without causing damage. The part is then ejected from the mold. After ejection, the part undergoes a series of post-processing steps, which might include trimming any excess material, machining to refine tolerances, and surface finishing to improve appearance or corrosion resistance. The final step is to inspect the part thoroughly to ensure the undercut features are correctly formed, and to verify that the overall dimensions and characteristics meet the required specifications.

Tools and Equipment Required

Successful diecast undercuts demand specialized tools and equipment, including precision-engineered molds with moving components like slides, lifters, and cams. These components are meticulously designed and manufactured to create the undercut features and ensure the part ejects without any damage. Die casting machines with high-pressure injection capabilities are essential, as they force molten metal into all the fine details of the mold, which includes the undercut. Additionally, precise temperature control systems are critical to regulate the mold and molten metal temperatures, ensuring efficient casting and part quality. Advanced simulation software is used to optimize the mold design and casting parameters. During post-processing, tools for trimming, machining, and finishing are used to meet specifications.

Common Challenges and Troubleshooting

Diecast undercuts can present a number of common challenges that need careful troubleshooting. One major problem is the potential for incomplete filling of the mold cavity, especially in the undercut regions. This can result from inadequate injection pressure, poor mold venting, or incorrect metal temperature, leading to incomplete features or defects. Another challenge is the risk of part distortion or warping during the cooling and ejection phases. This can often be addressed by optimizing the cooling rates, the mold design, or by using ejection aids to prevent the part from sticking or bending. Excessive flash, which is the unwanted excess material around the part edges, can result from worn or poorly aligned mold components. Regular inspection and maintenance are essential to identify and correct these issues.

Techniques for Different Undercut Designs

Various techniques are used to create different undercut designs in die casting, each requiring specific tooling and procedures. For external undercuts, such as those found on threaded holes or external lips, slides or side cores are often used. These components move laterally to create the undercut feature and retract before ejection. Internal undercuts, such as internal threads or recessed features, require the use of internal slides or collapsible cores. These cores are withdrawn or collapsed after casting, allowing the part to be removed. When dealing with complex undercuts, such as those with multiple angles or intricate geometries, advanced mold designs and specialized mechanisms may be necessary, often involving the use of cams, lifters, and other complex moving parts. Selecting the correct technique is critical to optimizing the manufacturing cost and ensuring the required part quality.

Optimizing Undercut for Production

Optimizing diecast undercuts for production involves a comprehensive strategy focused on efficiency, cost-effectiveness, and part quality. The optimization process starts with the design phase, where engineers should carefully consider the manufacturability of the undercut features, including draft angles and dimensions. The mold design is another key factor, and it should incorporate the appropriate moving components such as slides, lifters, or cams, designed for easy assembly, maintenance, and replacement. Proper mold temperature control helps in managing cooling rates and minimizing distortion. Process parameters like injection pressure, metal temperature, and cooling time must be finely tuned to minimize defects and increase production rates. Regularly evaluating the process using statistical process control methods will highlight areas for improvement and ensure consistent high-quality production.

Post-Processing and Finishing

Post-processing and finishing are essential steps in diecast undercut manufacturing, involving various processes to ensure the final product meets design and quality specifications. Trimming is often needed to remove excess material or flash that may have formed during the casting process. Machining operations, like drilling, tapping, and milling, are used to refine tolerances and incorporate additional features. Surface finishing techniques improve the part’s appearance, corrosion resistance, and wear properties. These can include plating, painting, powder coating, and various mechanical finishing operations. Careful selection of post-processing methods is crucial to meet the part’s specific requirements while balancing cost, quality, and production efficiency. Thorough quality control checks are performed at each stage to ensure the finished parts meet the expected standards.

Benefits of Using Undercuts in Diecasting

Diecast undercuts provide numerous benefits in manufacturing. They allow for creating complex part geometries that would be impossible with standard die casting techniques, increasing the design flexibility. This design flexibility leads to fewer components in the final product, which simplifies assembly, reduces material costs, and cuts manufacturing time. Parts with undercuts are often stronger and more functional, improving the performance and durability of the end product. They also help to reduce overall product weight and enhance efficiency in various industries like automotive, aerospace, and consumer electronics. The use of undercuts supports innovative designs and enables the production of highly specialized and complex parts.

Case Studies Successful Diecast Undercuts

Examining case studies provides valuable insights into how diecast undercuts are successfully applied across diverse industries. In the automotive sector, undercuts are frequently used to create complex engine components with integrated features. In consumer electronics, they enable intricate designs in housings and connectors, supporting miniaturization and improving functionality. In aerospace, undercuts are used in precision parts to ensure reliability and weight reduction. These case studies show how careful design and execution of the undercut process lead to innovative and effective solutions. Each successful implementation highlights the importance of choosing the correct undercut technique and how it helps to improve the performance, appearance, and overall value of the finished product. These examples serve as a guide for manufacturers and designers, showcasing the benefits and potential of diecast undercuts.