Diecasting aluminum is a fascinating and highly efficient process used to create complex metal parts with precision and speed. From intricate automotive components to robust consumer electronics, diecast aluminum parts are integral to countless products we use every day. This comprehensive guide will take you through the entire process, providing insights and tips to help you diecast aluminum like a pro.

What is Diecast Aluminum

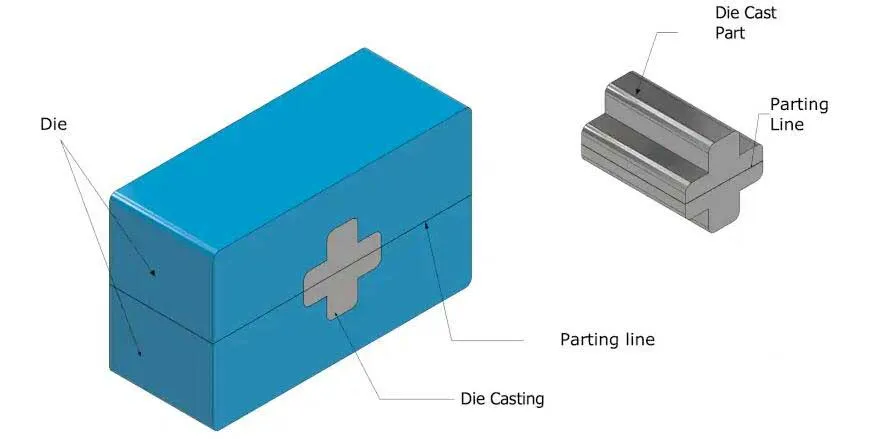

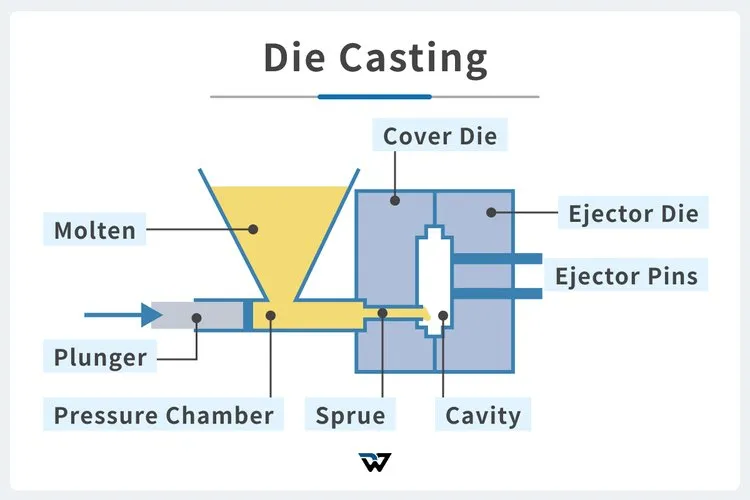

Diecast aluminum is a manufacturing process where molten aluminum alloy is forced under high pressure into a mold cavity. This mold, also known as a die, is typically made of steel and is designed to precisely shape the desired part. The high pressure ensures that the molten aluminum fills even the most intricate details of the mold. Once the metal cools and solidifies, the die is opened, and the finished part is ejected. This method is known for its ability to produce high volumes of parts with consistent quality and dimensional accuracy. The resulting components boast excellent mechanical properties, making them suitable for a wide array of applications.

The Advantages of Diecast Aluminum

Diecasting aluminum offers numerous benefits that make it a preferred choice for manufacturers across various industries. The advantages range from cost-effectiveness and design flexibility to the high-quality results. By understanding these advantages, one can better appreciate why diecast aluminum is such a popular choice for mass production. With this method, manufacturers can achieve tight tolerances, complex geometries, and superior surface finishes, all contributing to the overall quality and functionality of the final product.

Why Choose Aluminum Die Casting

Aluminum is an excellent material for die casting due to its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. These properties make aluminum die castings ideal for applications where weight reduction and durability are crucial. Furthermore, aluminum offers good thermal and electrical conductivity, enhancing its versatility in various industrial applications. The ability of aluminum to be cast into intricate shapes also allows for greater design freedom.

Cost-Effectiveness of Die Casting

Die casting is a highly cost-effective manufacturing process, especially for producing large volumes of parts. The initial tooling costs can be significant, but the high production rates and minimal waste contribute to lower per-unit costs as the volume increases. Additionally, the process allows for the creation of parts with net shapes, which reduces the need for secondary machining operations, further lowering costs. Aluminum’s recyclability adds an extra layer of sustainability, reducing material expenses and environmental impact.

Design Flexibility

Die casting offers unparalleled design flexibility, allowing manufacturers to create complex geometries that would be difficult or impossible to achieve with other manufacturing methods. The process can accommodate intricate details, thin walls, and complex shapes, enabling designers to optimize part performance and functionality. This capability makes it ideal for creating parts that require complex features, such as those found in automotive engines, electronic housings, and various consumer products. Design flexibility is one of the major reasons for the popularity of die casting.

Step-by-Step Guide to Diecasting Aluminum

Diecasting aluminum is a carefully orchestrated process involving several critical steps. Understanding each step is essential for producing high-quality parts consistently. From preparing the materials and designing the mold to the casting process and final finishing touches, each stage plays a vital role in the final product’s success. The following steps outline a detailed guide on how to diecast aluminum like a pro.

Preparation Phase

Before starting the casting process, meticulous preparation is vital for ensuring optimal results. This phase includes selecting the appropriate aluminum alloy, designing the mold (die), and preparing the die casting machine. Proper preparation will minimize defects and maximize the efficiency of the casting process. Accurate preparation lays the groundwork for a successful casting operation.

Material Selection

Selecting the right aluminum alloy is crucial. Different alloys have varying properties, such as strength, corrosion resistance, and thermal conductivity. Common aluminum alloys used in die casting include A380, A383, and ADC12, each offering different benefits depending on the application. Consider the specific requirements of the part, including its operating environment and intended use. The alloy choice will directly impact the final product’s performance and longevity. For example, A380 is a general-purpose alloy, while ADC12 is favored for its superior corrosion resistance.

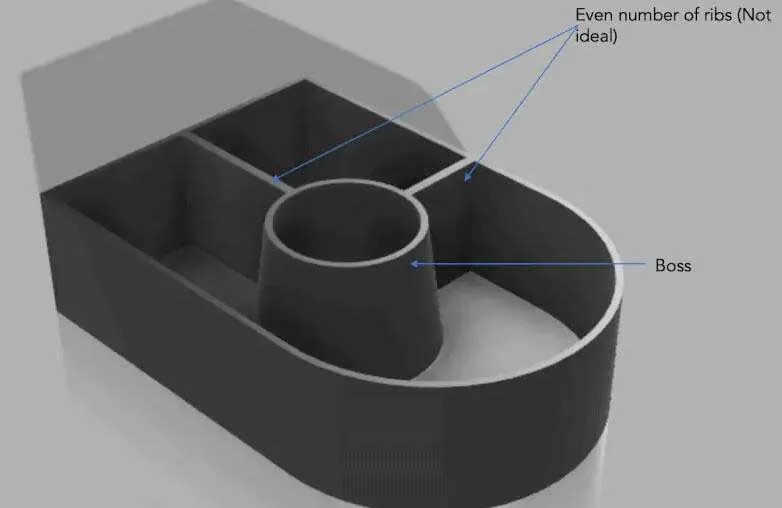

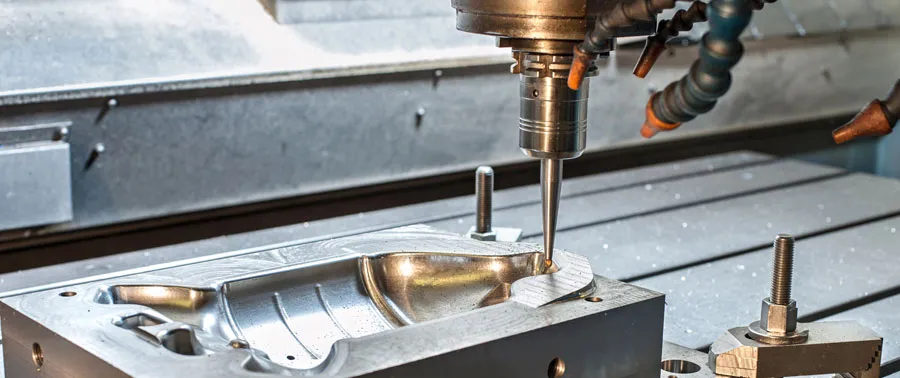

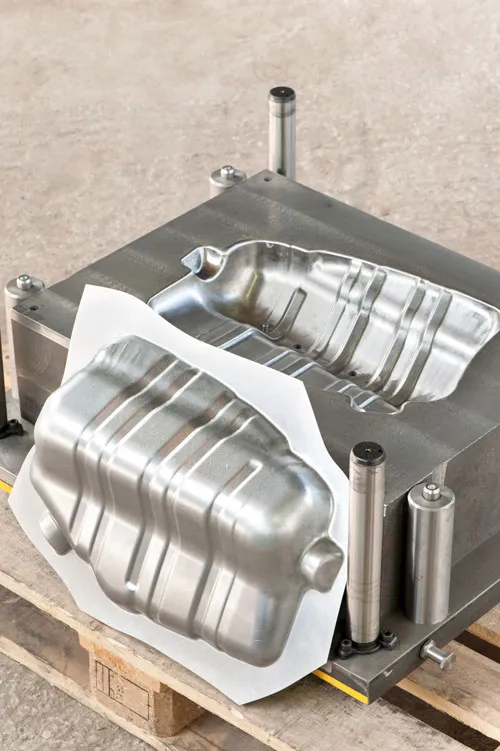

Mold Design

The mold, or die, is a critical component in the die casting process. A well-designed mold will ensure the proper shape, dimensions, and surface finish of the final part. Mold design involves creating the cavity where the molten aluminum will be injected, as well as designing the gating system (the channels through which the metal flows), the runner system, and the ejection system. The mold must also accommodate cooling channels to solidify the metal efficiently. Advanced software and precision machining are used to create high-quality molds that can withstand the high pressures and temperatures of the die casting process. See an example of aluminum die casting mold in the following image: https://example.com/aluminum-die-casting-mold.webp

Casting Process

Once the preparations are complete, the casting process can begin. This involves injecting molten aluminum into the mold under high pressure, allowing it to cool and solidify, and finally, ejecting the finished part. Each stage of the casting process is critical for achieving optimal results. The accuracy of these processes ensures the creation of precise and high-quality components.

Injection and Filling

The molten aluminum alloy is injected into the mold cavity under high pressure, typically ranging from 1,500 to 30,000 psi. The pressure forces the metal to fill all the intricacies of the mold quickly, ensuring a detailed and accurate part. The speed and pressure of the injection are carefully controlled to prevent defects such as porosity and cold shuts. The injection process is a precise operation that demands high-quality equipment and skilled operators. This stage is critical for determining the final properties of the diecast part. An example of a die casting machine: https://example.com/die-casting-machine.webp

Cooling and Solidification

After the mold is filled, the molten aluminum needs to cool and solidify. This process typically takes a few seconds to a minute, depending on the size and complexity of the part, as well as the mold’s design. Cooling channels within the die help to dissipate heat and accelerate solidification. Proper cooling is critical to minimize defects such as shrinkage and distortion. The metal solidifies from the outside in, forming a solid shell that encapsulates any remaining molten metal. Effective cooling management significantly affects the part’s mechanical properties.

Ejection and Trimming

Once the aluminum has solidified, the die is opened, and the part is ejected. Ejector pins, built into the mold, push the part out. After ejection, the part is trimmed to remove any excess material, such as gates, runners, and flash (thin excess metal formed at the parting line). Trimming can be done using various methods, including trimming dies, saws, or CNC machines. Accurate ejection and trimming ensure that the final part meets the required specifications. The final part will then be ready for further processing and finishing.

Finishing and Quality Control

The final stage involves finishing the part to meet its specifications and ensuring its quality. Surface treatments, such as painting, plating, or powder coating, can improve the part’s appearance, corrosion resistance, and wear resistance. Quality control checks are performed throughout the process to identify and correct any defects. These steps guarantee that the final product meets the highest standards of quality. A key element to a good process is the utilization of a quality control process. An example image: https://example.com/quality-control-diecast.webp

Surface Treatment

Surface treatments enhance the appearance and functionality of diecast aluminum parts. Common treatments include painting, powder coating, anodizing, and plating. Painting provides a protective layer and aesthetic appeal. Powder coating offers excellent durability and corrosion resistance. Anodizing creates a hard, durable, and corrosion-resistant surface, and plating improves wear resistance and provides decorative finishes. The choice of surface treatment depends on the application requirements and aesthetic preferences. An example of the finishing process: https://example.com/aluminum-casting-surface-treatment.webp

Quality Checks

Quality control is an essential aspect of die casting, ensuring that all parts meet the required specifications. This includes dimensional checks, visual inspections, and mechanical testing. Dimensional checks involve verifying the accuracy of the part’s dimensions using tools like calipers, micrometers, and coordinate measuring machines (CMMs). Visual inspections identify surface defects and imperfections. Mechanical testing, such as tensile strength and hardness tests, confirms the part’s mechanical properties. A robust quality control program minimizes defects and ensures consistent product quality. See an example of the final parts: https://example.com/die-cast-aluminum-parts.webp

Common Issues and Troubleshooting

While die casting is a highly reliable process, certain issues can arise. Understanding these issues and how to troubleshoot them is crucial for ensuring high-quality parts. The most common defects include porosity, shrinkage, and warpage. By learning to identify the causes and implement corrective measures, manufacturers can improve their die casting process and produce superior products. This section will discuss some common problems and how to address them.

Porosity and Gas Entrapment

Porosity refers to the presence of voids or gas pockets within the casting, weakening the part and potentially affecting its appearance. Gas entrapment occurs when air or other gases become trapped in the molten metal during the casting process. This can be caused by various factors, including high injection speeds, improper venting, or contamination of the molten metal. To mitigate porosity, ensure that the molten aluminum is properly degassed and the mold is vented correctly. Controlling injection parameters and maintaining proper metal cleanliness are also crucial. The quality of the final product depends on minimizing porosity.

Shrinkage Defects

Shrinkage defects occur when the molten aluminum solidifies and contracts, leading to voids or depressions in the casting. This is a natural consequence of the metal cooling and solidifying. Shrinkage defects are often found in thick sections of the casting. Proper mold design and cooling management can help prevent these defects. Using chills or strategically placed cooling channels can promote uniform cooling and minimize shrinkage. Careful control of the casting temperature and injection pressure also help to minimize shrinkage.

Warpage

Warpage is a distortion or bending of the casting that can occur during the cooling process. This often results from uneven cooling, which can cause differential stresses within the part. Warpage is especially common in castings with thin walls or complex geometries. To minimize warpage, ensure uniform cooling throughout the mold. Optimize mold design to reduce stress concentrations. Proper gating and venting can also help to alleviate warping. Sometimes, post-casting heat treatments can be employed to relieve internal stresses and minimize warpage.

Tips for Diecasting Success

Achieving success in diecasting aluminum requires attention to detail and a commitment to best practices. By following the tips discussed throughout this guide, manufacturers can improve part quality, reduce waste, and optimize production efficiency. The key to success lies in careful planning, meticulous execution, and continuous improvement. With dedication and the right knowledge, anyone can master the art of diecasting aluminum and produce high-quality parts consistently.

By following the steps outlined in this guide and paying close attention to the details, you can master the art of diecasting aluminum. With experience and continuous improvement, you’ll be able to produce high-quality parts that meet the highest standards. The ability to diecast aluminum is a valuable skill that can open doors to new opportunities in manufacturing and engineering.